Special measuring devices

Our core competency is the development and manufacture of special measuring devices for the following workpiece categories:

- constant velocity joints

- transmission parts

- axel and steering parts

- engine parts

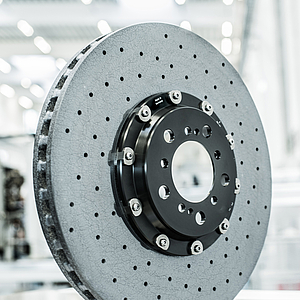

- wheels/rims

- aluminum parts

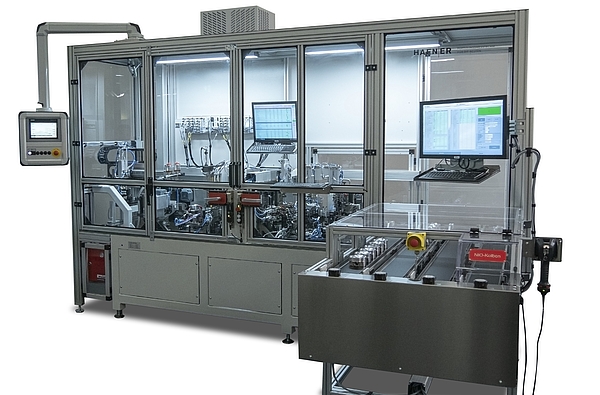

Our product range starts with manual measuring stations and includes fully automated measuring machines. The integration of different sensors and components enables solutions for very complex measuring and inspection tasks. This is why we are experts when it comes to tactile, pneumatic and optical measuring systems as well as hardness, crack and surface testing. Weighing technology, labeling and sorting are also components of our comprehensive systems. Their robustness guarantees good functionality and measuring accuracy even in a harsh manufacturing environment. This enables our customers to very accurately assess their manufacturing process – even for critical components – and therefore obtain a high level of productivity. As an independent company, we use the best possible components. New tasks can be implemented quickly, cost-effectively and reliably by using tried and tested modules and components. The measurement of all the linear measures (height, thickness, groove and web width), form (concentricity, parallelism and angle) and position tolerances ( dimension between axes, drilling position and symmetry) are the central tasks of our measuring Systems.